Silk Screen & Pad Print

Putting realistic graphics on the prototype is essential to realistic representation of the product. Our graphics can be applied with silk-screening, pad printing, laser & acid etching, engraving, stamping and various other methods. No matter if it’s a 3D graphics that you needed some depth with, or a crisp gloss-finished logo that needs to be etched on to a textured surface, we can achieve your desired result.

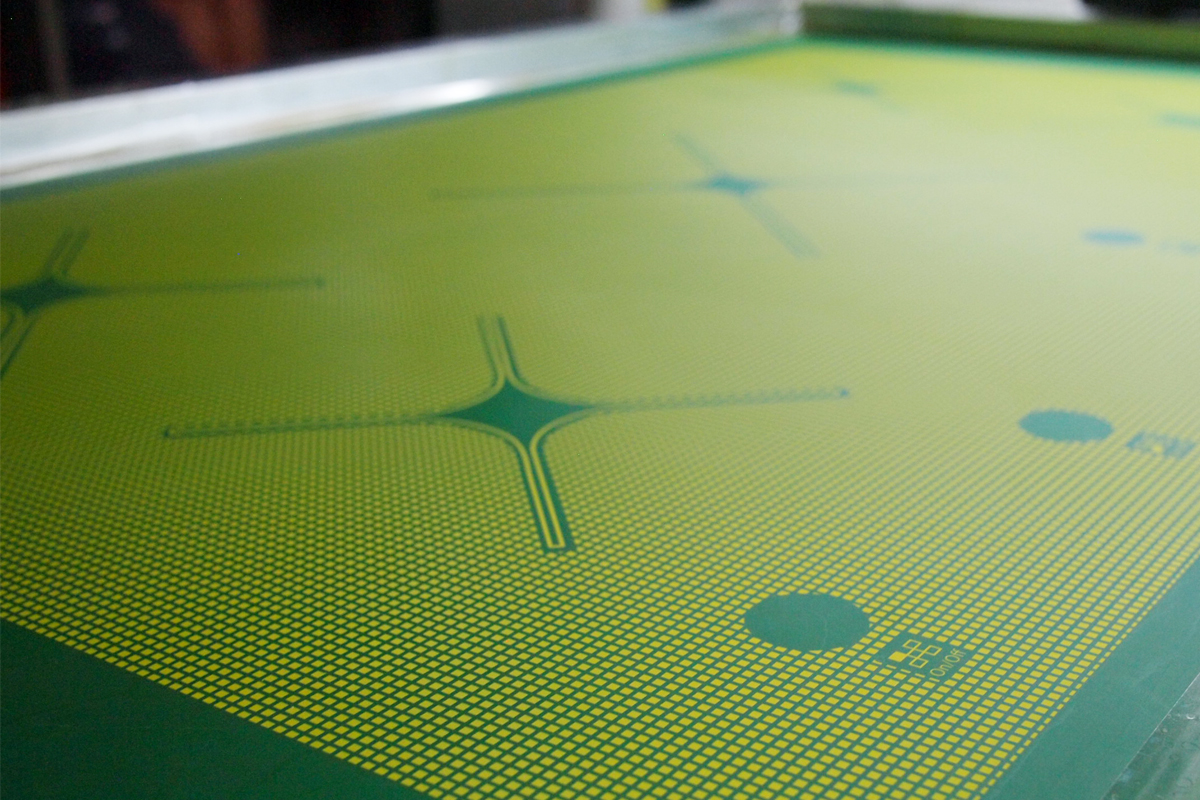

Screen printing is a printing technique that uses a woven mesh to support an ink-blocking stencil to receive a desired image. The attached stencil forms open areas of mesh that transfer ink or other printable materials which can be pressed through the mesh as a sharp-edged image onto a substrate. A fill blade or squeegee is moved across the screen stencil, forcing or pumping ink through the mesh openings to wet the substrate during the squeegee stroke. Basically, it is the process of using a mesh-based stencil to apply ink onto a substrate, whether it be t-shirts, posters, stickers, vinyl, wood, or other material.

Laser engraving, is the practice of using lasers to engrave an object. Laser marking on the other hand just discolors the surface, without cutting into the surface. The technique does not involve the use of inks, nor does it involve tool bits which contact the engraving surface and wear out. These properties distinguish laser engraving from alternative engraving or marking technologies where inks or bit heads have to be replaced regularly.